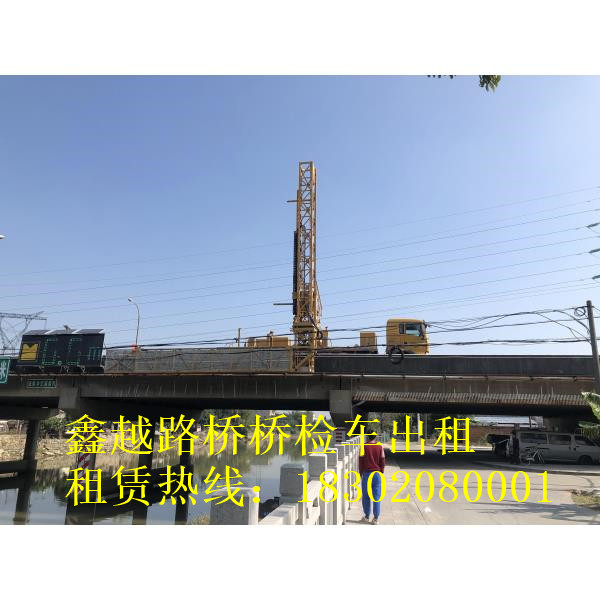

Huiyang bridge bottom oil paint brush new car rental bridge stuffed car rental Xin Yue Road bridge free consultation hotline 135-0000-3760, Fang Ms. WeChat mobile phone with the same number, all year round, contact. It is more difficult to encounter deep water. According to the construction experience and the actual situation, the top rising can be directly implemented under the top surface of the pier beam and the hollow plate beam flapboard, but the tens of thousands of top height is not more than 3 cm. For this purpose, "ultra low high airbag jack" can be implemented. Preparation works in the shared position to set the operating platform for anhydrous velocity to take a stent mode, and use the ordinary scaffolding steel pipe and the fastener; for the water pier, the bracket is used. The intensity and stability of the stent should meet the requirements of the operation safety. After the bracket is completed, the mount holder is fully inspected and recorded and numbered. According to the inspection, determine the replacement of the seat, bridge, and quantity, and develop the best support replacement plan according to the traffic operation ". Clean up the jack before the job, so that it is stable for the jack and the placement of the pad. At the same time, it is determined that the pad used by the jack, the pad is used as a steel plate (thickness 10 mm).

The size shall not be less than 14Cm × 14cm, placed in front of the corresponding plate-shaped support, and prepare a certain number of thin steel plates or wedge steel sheets to facilitate super pad wedges during the tape rising process. The airbag jack, the trachea, the load test should be carried out to test the effectiveness of each device. 3.4 Trial top support rack, operation platform, you can try it after the jack is installed. (1) The temperature measurement hole should be drawn and numbered. Generally, the process flow of bridge reinforcement: steel sheet fabrication ~ concrete surface and steel sheet surface treatment ~ adhesive ~ rubber ~ drilling, rivet fixed steel plate ~ test. In the most important construction project in our lives, first, the maintainer must be unified to pay attention to the regular inspection process, and then effectively guarantee the security of the construction system in uniform use, first take the most professional departments. The bridge holder attached to the bridge is more important. The important factors you have to pay attention to in successful use, first, there is a need for unity to attract our common concern. Huiyang bridge bottom oil paint brush new car rental bridge stuffed car rental Xin Yue Road bridge free consultation hotline 135-0000-3760, Fang Ms. WeChat mobile phone with the same number, all year round, contact.

So today, we will find out about the problem that the bridge support should be paid attention to in daily maintenance. The bridge holder replaces the relevant matters you have to pay attention to in every maintenance link. This aspect should be uniformly attracted to our common concern, and it can also effectively improve the considerable presence of such operations in the future development, then today is Let's take a look at the relevant matters related to the bridge support to replace the bridge holder. Different top rises should be used in different forms of bridges. For cross-sectional forms composed of T beams or work-beams, it is generally carried out in the beam body to install the pads directly under jacks; however, when the hollow plate, the box beam, you must pay attention to the top, avoid Direct tops directly, it is easy to select in two ribs and box girder webs to prevent damage to the beam body. Since the edge beam itself is self-respecting and the effect of bridge appended attachment facilities (such as the guardrail, the connecting part of the distribution).

The difference between the tensilength is larger, and must be pressure and stroke dual control at the top of the rising, and the stroke is ultimately controlled. Avoid cutting destruction of the bridge surface due to uneven starting top. Rational running every important part, first of all the prime minister, this area is necessary to unify us to pay attention to us, that is, the bridge holder replacement in the unified implementation process, often the most favorable maintenance method is effective Guarantee the key to security. 1. Cooking steel sheet. The steel sheet is made into a steel strip according to the specifications and sizes required by the anchor steel plate, and the rivet is riveted on the steel plate. The production requirements of the steel sheet are basically flat, 2. Concrete surface treatment. Slightly chisel the concrete loose layer, so that the concrete surface is substantially flat, then the concrete connected to the steel plate bond surface is placed flat, and the surface floating floss is brush, and the steel sheet will be passed. The binder is blown. For the excessive depression of the concrete surface.

Apply a repair material to handle surface. 3. Steel plate surface treatment. The steel sheet was ground to the metal gloss, and then coarse grinded with a crude sandwheel, and the stripping path was vertically in the direction of the steel plate. 4. Human glue and rubber. After the structuring is prepared, the thickness is applied to the concrete surface of the condensation, the thickness is preferably 1-3 mm, and the thickness is thin and then paste the steel plate to the predetermined. 5. Drilling, rivet the steel sheet. After the steel sheet is booked, it should be immediately rivetled. After the shaped rivet, the shaped rivet is all increed, and the steel sheet is stretched by the rivet to ensure that the steel sheet is tightened in the force direction, and the steel plate is firmly riveted to reinforcement On the component, the structural adhesive extruded from the edge of the steel sheet by extrusion. 6. Quality inspection. Steel plates and architectural adhesive materials should have relevant material certificates and product certificates, and conduct on-site sampling inspection of steel plates and structures. The rivet site sampling, a single rivet anti-shear test in the laboratory.

A single rivet anti-shear force is qualified. (2) The thermometer should be separated from the outside air temperature and should be left for no less than 3 minutes in the temperature measuring hole. When the temperature is measured, when maintaining the heat storage method, it should be placed in a cooling site; when using a heating method When maintenance is maintained, it should be set separately from the heat source. The thickness structure should be set separately in the surface and the interior. 6) When the concrete winter is constructed, in addition to the standard maintenance test piece, and the same number and the structural adherent maintenance should be made. For concrete structures maintained by steam heating, in addition to preparing standard maintenance test parts, it should be carried out at the same time as the concrete structure is steamed, and then maintain the 28D test under standard conditions to check the concrete after steaming. The strength of 28D. Evaluation Method of Concrete Quality in Winter Times The same as the construction of concrete in normal temperature. Before the replacement is replaced, the temporary power structure should be considered in accordance with the actual geological conditions at each bridge (Taiwan), and the small excavator is used with the artificial excavation of the earth and the earth-stacked earth. Huiyang bridge bottom oil paint brush new car rental bridge stuffed car rental Xin Yue Road bridge free consultation hotline 135-0000-3760, Fang Ms. WeChat mobile phone with the same number, all year round, contact.